Scalable, inexpensive, solventless and great for the environment

Revolutionary extraction technology just waiting for your artistry.

Imagine an extraction process that is so safe, consistent and precise that you can develop products with the art of a craft brewer or winery.

EVO Extracts’ technology is so precise that producers can extract precise fractions from their strains, time and time again, refining those elements into products that are a cut above anyone else’s. Now imagine that the EVO Extracts’ technology is not only more precise, it’s also scalable, inexpensive, efficient, solventless and great for the environment. Imagine no more. That technology is here, and easy to afford through EVO Extracts’ “tolling” business model. Current extraction methods are inefficient, imprecise, expensive and slow. The most common method, CO2 extraction, is not able to fraction individual cannabinoids effectively and pulling terpenes?... not a chance!

Other methods involve dangerous hydrocarbons that are not just bad for the environment, they also impact the quality and pureness of the oil. Depending on the manufacturer, additional steps are required to reclaim solvents, filter the oil and remove waxes and lipids. EVO doesn’t need any of these costly, time-consuming steps! But does this so-called purging process actually work? Are chemicals and solvents removed completely?

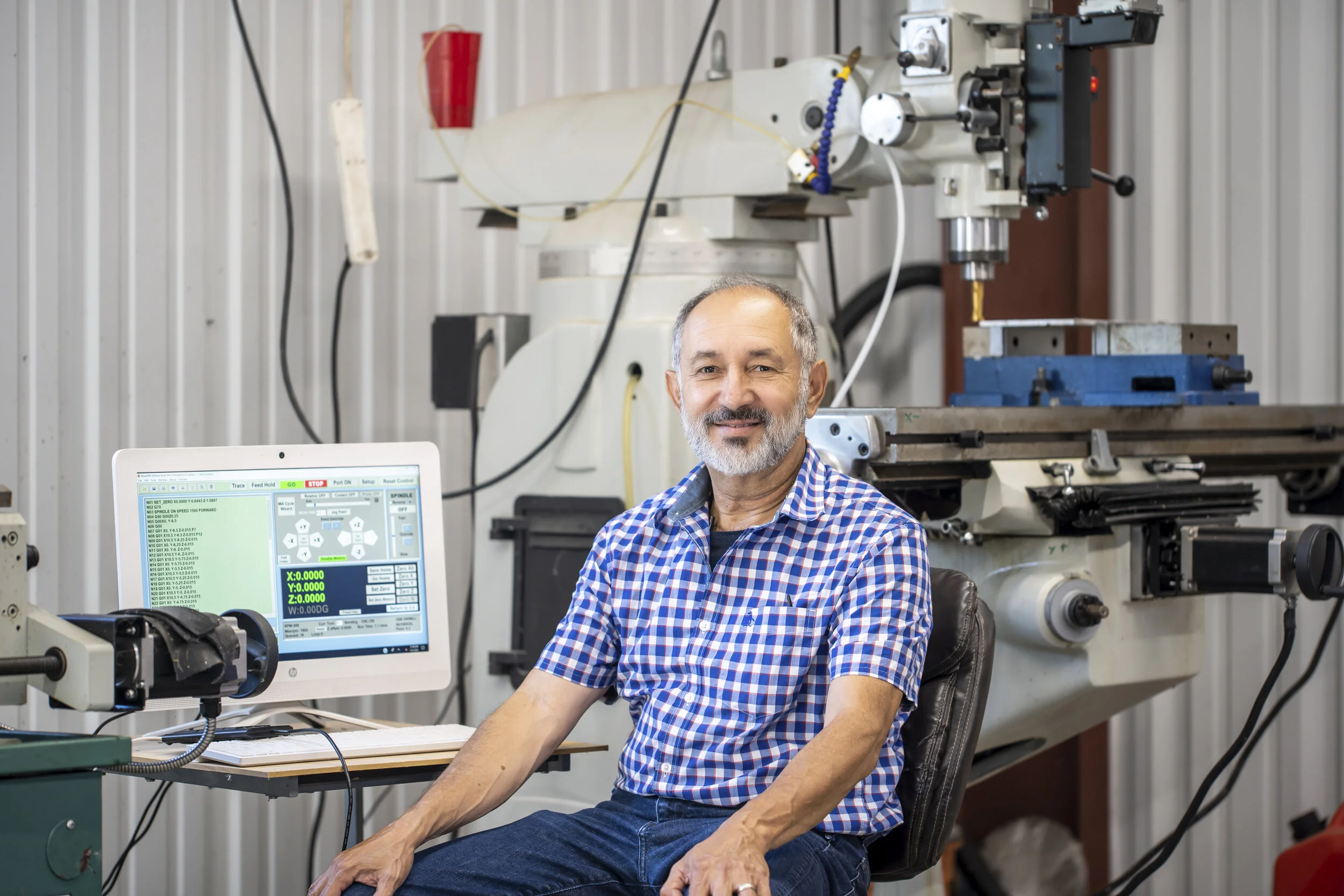

Health-conscious consumers do not want to ingest products made with solvents. People who use oils for health issues will naturally reach for products made in a safe, environmentally friendly way that is far removed from potentially deadly solvents. That’s where EVO Extracts’ revolutionary manufacturing process becomes such a game changer in the extraction industry. Developed by world-class electronics engineer Gilbert Fregoso, EVO Extracts’ processing machines use thermal evaporation and deposition technologies.

By thinking outside the box, Gilbert has modified a well established industrial process used traditionally with non-organic materials and applied it within the cannabis and hemp industry. The result, accomplishing what has never been done before. Providing a scalable, efficient, solventless method of oil extraction. At a little more than seven feet long, four feet deep and six feet high, these relatively small machines take cannabis or hemp and produce a pure distillate that can be “tweaked” to customer preference. Want the terpenes fractioned? We can do that. Want all the THC removed? Yes, we can do that. Want a full spectrum oil? Again, yes we can do that. You tell the EVOlution what you want and it takes it from there!

Using precise temperatures, pressures and flow rates, biomass is passed on our patent-pending delivery system. At each stage, the EVOlution precisely fractions off components eventually leaving the biomass free of terpenes and cannabinoids. The system uses completely inert gasses and a patented hurricane-like venturi delivery system, extracting first terpenes and a variety of cannabinoids (including THC) through condenser heads and into collecting flasks.

Like craft beer brewers, producers can choose exactly which components they wish to extract, enabling them to manufacture consistent products based on individual tastes. In fact, EVO Extracts supplies ready-made recipes for individual cannabis and hemp strains so producers can start manufacturing extracts under pre-set conditions. These recipes can be refined and redesigned as extractors develop their own specialized products. In the end, any residual biomass can be used as valuable compost, allowing for a completely green extraction process.